Nenhum produto no carrinho.

Science behind Hydrogen supplementation

A multicylinder reciprocating engine was used to extend the efficient lean operating range of gasoline by adding hydrogen. Both bottled hydrogen and hydrogen produced by a research methanol steam reformer were used. These results were compared with results for all gasoline. A high-compression-ratio, displacement production engine was used. Apparent flame speed was used to describe the differences in emissions and performance. Therefore, engine emissions and performance, including apparent flame speed and energy lost to the cooling system and the exhaust gas, were measured over a range of equivalence ratios for each fuel. All emission levels decreased at the leaner conditions. Adding hydrogen significantly increased flame speed over all equivalence ratios.

Source : National Aeronautics and Space Administration / Authors : J.F. Cassidy

***

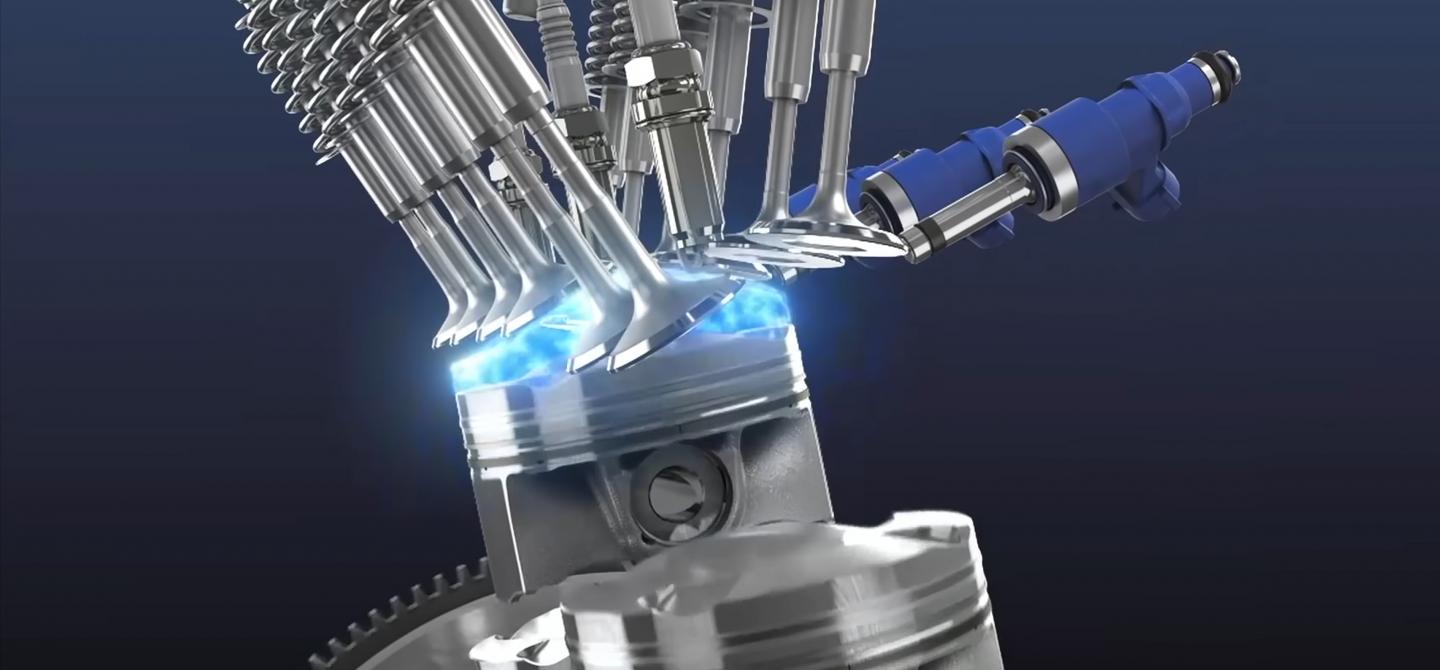

The presented concept for a SI-engine consists of combined injection of gasoline and hydrogen. A hydrogen enriched gas mixture is being injected additionally to gasoline into the engine manifold. The gas composition represents the output of an onboard gasoline reformer.

The simulations and measurements show substantial benefits to improve the combustion process resulting in reduced cold start and warm up emissions and optimized part load operation. The replacement of gasoline by hydrogen-rich gas during engine start leads to zero hydrocarbons in the exhaust gas. The mixed fuel operation enables high EGR rates up to 50% or extended lean burn limits resulting in reduced pumping losses and increased effective engine efficiency.

Source : Society of Automotive Engineers / Authors : T. Allgeier, M. Klenk, T. Landenfeld, E. Conte, K. Boulouchos, J. Czerwinski

***

Article : A Study of Combustion of Hydrogen-Enriched Gasoline in a Spark Ignition Engine

An investigation has been done on the influence of small amounts of hydrogen added to hydrocarbons-air mixtures on combustion characteristics.

Experiments carried out with a single-cylinder four stroke SI engine confirmed the possibility of expanding the combustion stability limit, which correlates well with the general trend of enhancing the rate of combustion. An increase of brake thermal efficiency has been obtained with a reduction of HC emissions; the NOx emissions were higher, except for very lean mixtures.

Source : Society of Automotive Engineers / Authors : N. Apostolescu, R. Chiriac

***

The addition of hydrogen-rich gas to gasoline in an Internal Combustion Engine seems to be particularly suitable to arrive at a near-zero emission Otto engine, which would be able to easily meet the most stringent regulations.

In order to simulate the output of an on-board reformer that partially oxidizes gasoline, providing the hydrogen-rich gas, a bottled gas has been used.

Detailed results of our measurements are here shown, such as fuel consumption, engine efficiency, exhaust emissions, analysis of the heat release rates and combustion duration, for both pure gasoline and blends with reformer gas. Additionally simulations have been performed to better understand the engine behaviour and NOx formation.

Results show that:

- When running at λ=1 and without EGR, addition of hydrogen-rich gas produces a significant shortening of the very first phase of combustion (inflammation phase) rather than of the remaining combustion process;

Addition of hydrogen-rich gas allows to run the engine at extremely high λ or EGR rate; - When running at the highest possible λ or EGR (limited by COV increase) the duration of all phases of combustion remains almost unaffected by the diluents;

- In all conditions a significant decrease of UHC and NOx emissions has been observed;

- In all conditions a significant increase of engine efficiency has been measured, which seems to be enough to compensate and overcome the losses due to the partial oxidation of Gasoline in the Reformer.

Source : Society of Automotive Engineers / Authors : E. Conte, K. Boulouchos

***

Hydrogen and gasoline can be burned together in internal combustion engines in a wide range of mixtures. In fact, the addition of small hydrogen quantities increases the flame speed at all gasoline equivalence ratios, so the engine operation at very lean air-gasoline mixtures is possible. In this paper, the performance of a spark-ignition engine, fuelled by hydrogen enriched gasoline, has been evaluated by using a numerical model. A hybrid combustion model for a dual fuel, according to two one-step overall reactions, has been implemented in the KIVA-3V code. The indicated mean pressure and the fuel consumption have been evaluated at part load operating points of a S.I. engine designed for gasoline fuelling. In particular, the possibility of operating at wide-open throttle, varying the equivalence ratio of air-gasoline mixture at fixed quantities of the supplemented hydrogen, has been studied.

Source : Society of Automotive Engineers / Authors : G. Fontana, E. Galloni, E. Jannelli, M. Minutillo

***

Article : Combustion Optimization in a Hydrogen-Enhanced Lean Burn SI Engine

This paper details an experimental combustion system optimization program. Experiments focused on three key areas: the ignition system, in-cylinder charge motion produced by changes in the inlet ports, and uniformity of fuel-air mixture preparation.

Results indicate that optimizations of the combustion system in conjunction with hydrogen-enhancement can extend the relative air/fuel ratio λ at the lean limit of operation by roughly 25% compared against the baseline configuration. Nearly half of this improvement may be attributed to improvements in the combustion system. Furthermore, hydrogen-enhancement produces a nearly constant lean misfire limit improvement of ∼ 0.20 – 0.25 λ values, regardless of baseline combustion behavior. In contrast, the improvement of the amount of dilution with excess air at the point of peak engine efficiency decreases as engine operation becomes leaner, due to the inherently lengthening burn duration as λ increses.

Source : Society of Automotive Engineers / Authors : J. Goldwitz, J. Heywood

***

It is well known that hydrogen addition to spark-ignited (SI) engines can reduce exhaust emissions and increase efficiency. Micro plasmatron fuel converters can be used for onboard generation of hydrogen-rich gas by partial oxidation of a wide range of fuels.

With hydrogen supplement to the main fuel, SI engines can run very lean resulting in a large reduction in nitrogen oxides (NOx) emissions relative to stoichiometric combustion without a catalytic converter. This paper presents experimental results from a microplasmatron fuel converter operating under variable oxygen to carbon ratios.

Tests have also been carried out to evaluate the effect of the addition of a microplasmatron fuel converter generated gas in a 1995 2.3-L four-cylinder SI production engine. The tests were performed with and without hydrogen-rich gas produced by the plasma boosted fuel converter with gasoline. A one hundred fold reduction in NOx due to very lean operation was obtained under certain conditions.

Source : Society of Automotive Engineers / Authors : J. Green, L. Bromberg, D. Cohn, A. Rabinovitch, N. Domingo, J. Storey, R. Wagner, J. Armfield

***

This research involved studying the effects of adding small amounts of hydrogen or hydrogen and oxygen to a gasoline fuelled spark ignition (SI) engine at part load. The hydrogen and oxygen were added in a ratio of 2:1, mimicking the addition of water electrolysis products. It was found that the effects of hydrogen addition (≈ 2.8% of the fuel by mass, ≈ 60% by volume) decreased as the fuel/air equivalence ratio approached ϕ = 1. When operating at ϕ ≤ 0.8, the torque, indicated mean effective pressure (imep) and NO emissions increased and cycle-to-cycle variation decreased with hydrogen addition. The improvements in engine performance and increase in NO emissions were related to a faster burn rate shown by a decrease in burn duration with the addition of hydrogen. Further, the addition of hydrogen only and hydrogen and oxygen in a ratio of 2:1 were compared. The extra oxygen had little effect on engine performance other than an increase in NO exhaust concentration ∼ 500 ppm. Under the conditions tested, the power necessary to generate the hydrogen on board through electrolysis was greater than what was gained from the engine.

Source : Society of Automotive Engineers / Authors : P. Henshaw, T. D’Andrea, D.Ting, A. Sobiesiak

***

Article : On-Board Hydrogen Generator for a Partial Hydrogen Injection Internal Combustion

A compact onboard hydrogen generator has been developed for use with a hydrogen-enriched gasoline internal combustion engine.

A study of the theoretical equilibrium product composition has indicated an optimum operating point at an air/fuel ratio of 5.15, where a hydrogen/fuel mass ratio of 0.136 can be obtained under soot-free conditions. This is based on a gasoline with an atomic hydrogen to carbon ratio of 1.92.

The calculated effect of hydrogen generator operating conditions on the fuel efficiency of a generator/engine combination is presented.

Source : Society of Automotive Engineers / Authors : J. Houseman, D. Cerini

***

Article : Effects of Hydrogen Addition to SI Engine on Knock Behavior

In an SI engine, increasing the compression ratio could be one mean of achieving higher thermal efficiency. However, when the compression ratio is increased, knock occurs and it prevents higher thermal efficiency. It is generally known that if the burning velocity is increased and the combustion period is shortened, the occurrence of knock may be suppressed. Here, hydrogen was added to the gasoline engine as a mean of increasing the burning velocity. As a result, it has been confirmed that the occurrence of knock could be controlled to some extent, and knock could be completely avoided depending on the conditions for the distribution of hydrogen. Furthermore, it became clear that this result might have originated not only by the increase in the burning velocity but also by the hindrance of radical production by the hydrogen.

Source : Society of Automotive Engineers / Authors : T. Shinagawa, T. Okumura, S. Furuno, K. Kim

***

Article : Onboard Hydrogen Generation for Hydrogen Injection into Internal Combustion Engines

A system is described for onboard hydrogen generation in an internal combustion engine. The hydrogen is produced from methanol reacting with steam in recirculated exhaust gas over a Ni-catalyst. The energy for the reaction is supplied by the exhaust waste heat. The hydrogen is used to extend the lean limit of the gasoline in order to achieve higher efficiency and lower pollutant emissions.

A theoretical study of the required amount of recirculated exhaust gas has been made and the energy efficiency of the reactor has been calculated. The produced and the required amount of hydrogen have also been calculated.

A stationary test engine using the system is presented.

The results show a potential for very low pollutant emissions with an increased energy efficiency compared to that of a conventional engine.

Source : Society of Automotive Engineers / Authors : K. Sjarstrarm, S. Eriksson, G. Landqvist

***

Article : Lean-Burn Characteristics of a Gasoline Engine Enriched with Hydrogen Plasmatron Fuel Reformer

When hydrogen is added to a gasoline fueled spark ignition engine the lean limit of the engine can be extended. Lean running engines are inherently more efficient and have the potential for significantly lower NOx emissions. In the engine concept examined here, supplemental hydrogen is generated on-board the vehicle by diverting a fraction of the gasoline to a plasmatron where a partial oxidation reaction is initiated with an electrical discharge, producing a plasmatron gas containing primarily hydrogen, carbon monoxide, and nitrogen.

All of the data was compared to a baseline case of the engine operating stoichiometrically on gasoline alone. It was found that the peak net indicated fuel conversion efficiency of the system was increased 12% over the baseline case. In addition, at this peak efficiency point the engine out NOx emissions decreased by 94% (165ppm vs. 2800ppm) while the hydrocarbon emissions decreased by 6%.

Source : Society of Automotive Engineers / Authors : E. Tully, J. Heywood

***